10 Simple Techniques For Digital Printing

10 Simple Techniques For Digital Printing

Blog Article

The Only Guide for Digital Printing

Table of ContentsDigital Printing Fundamentals ExplainedDigital Printing Can Be Fun For AnyoneThe 6-Minute Rule for Digital PrintingSome Known Questions About Digital Printing.The Ultimate Guide To Digital PrintingExamine This Report about Digital PrintingThe Ultimate Guide To Digital Printing

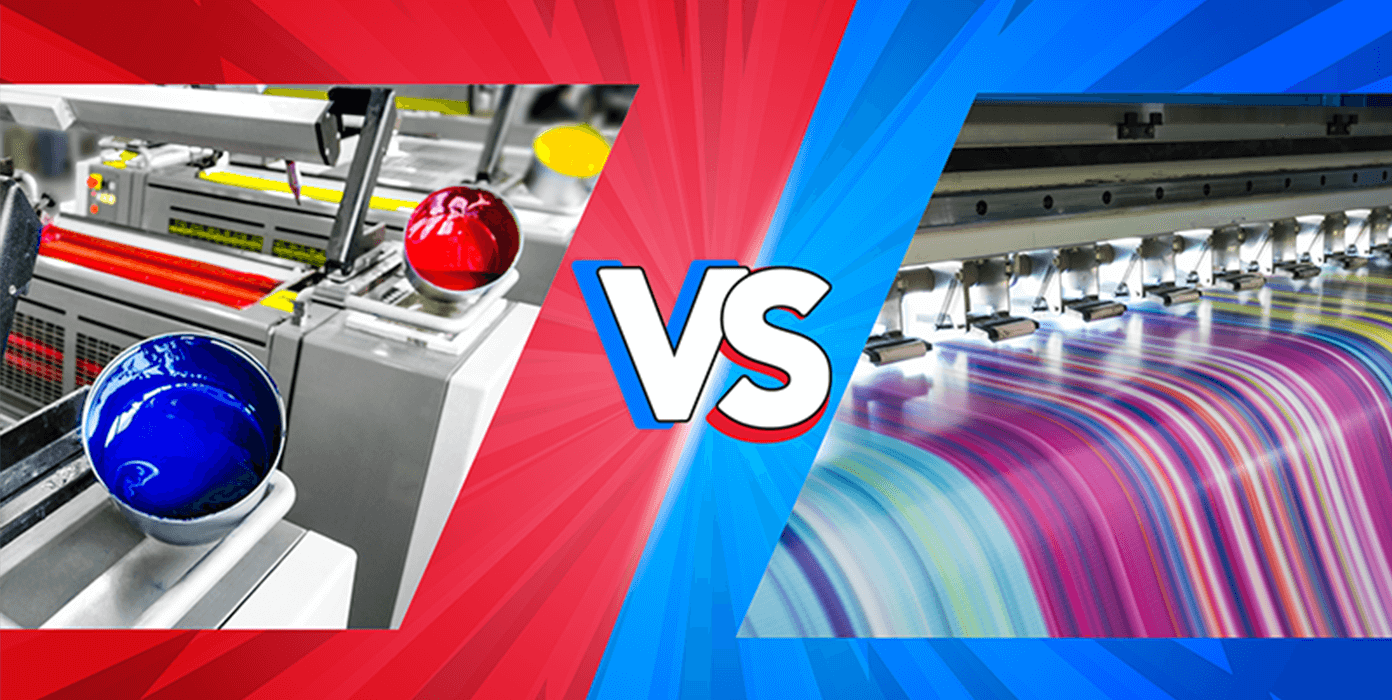

Unlike countered printing (or lithography), digital printing does not utilize damp ink to transfer photos making use of printing plates (Digital Printing). Rather, digital printers use a photo documents, such as a PDF, to draw up the and recreate it. Configuration is much faster than countered printing, as there are no plates to create and the electronic printer takes care of every little thingToner-based presses utilize electrophotography, or powder-based pigmented toner that's gotten by an electrical drum and rolled onto the paper or product. Fragments that create a picture are after that integrated to the product utilizing a laser. Toner-based presses were the initial digital printing technique and proceed to stay popular today as a result of their capability to generate high-definition results and print on a wide variety of products.

The inkjet printing process includes liquid ink cartridges and nozzles that spray ink out in a mist over an assigned picture or pattern. Inkjet modern technology has actually progressed swiftly considering that its innovation and is currently used in industrial applications such as fabric printing, signs, and porcelains, too paper. The current generation of inkjet presses are qualified of generating top quality that goes beyond Toner-based presses and also conventional countered presses.

All that's needed to create a digital print is a high-res photo documents. Once that has actually been posted, the printer takes care of the remainder, considerably lowering turn-around times for jobs that don't call for big quantities. If your task has a limited due date, electronic printing may be a terrific alternative to check out.

Some Known Questions About Digital Printing.

The new generation of inkjet presses, like Fuji's J Press, are capable of printing at a top quality degree, color range, and consistency that exceeds also the ideal conventional countered presses. When timing is a concern, digital printing can be a wonderful option. If your job includes a larger amount (i.e.

The Definitive Guide for Digital Printing

We've covered have actually gamut of digital printing electronic and disadvantages.

Digital printing is scalable for reduced and high volumes. For highly detailed, visually appealing applications such as prime tags, digital printing makes certain quality and uniformity, no issue exactly how huge the quantity.

Getting My Digital Printing To Work

It utilizes less materials and produces less waste, as there's no demand for plates or excess ink (Digital Printing). Furthermore, digital printing boosts the deinkability and recyclability of printed products. Digital printing is versatile for numerous printing products and thicknesses. Digital printing guarantees outstanding attachment on a selection of substrates. It likewise gives high readability, which is critical for transmitting details in industrial applications.

Digital printing uses extra flexibility and innovative opportunity. Other printing approaches require considerable time for the ink to completely dry, however digital printing dries immediately.

Digital printing is an excellent selection when it concerns conforming with rigorous food get in touch with and security regulations. Some printing can be non-toxic and odorless for food packaging applications. This one-of-a-kind feature is crucial for sticking to FDA and business printing guidelines. Being non-toxic, some electronic printing complies with safety standards for children's toys and clothing.

Our state-of-the-art devices enables us to publish applications with resolutions of as much as 1,200 dpi and up to 98 ft. per minute. Our digital printing offers exceptional lightfastness, one-pass nontransparent white, a broad option of shades, and the satisfaction of being odor free, food-safe, and eco-friendly. Apart from our printing abilities, Tapecon offers excellent solution and expertise.

Get This Report on Digital Printing

With over 100 years of manufacturing experience, Tapecon functions with item groups to fix challenges, produce items, and boost lives. Discover much more concerning our sturdy printing and layer solutions.

Plateless electronic printing makes possible multi-product, low-volume printing in a restricted printing time and cheaper. A restricted printing time allows various printing patters, depending on specific requirements, creativity or seasons.

Numerous design opportunities with complete shade and rank print without the limitation of shades. Complete color print is performed in one process without utilizing plates. It makes it possible for quick delivery. It is now possible to develop a solitary example which have the same quality when contrasted the end product with go to website the initial style.

Some Ideas on Digital Printing You Should Know

Analog printing requires times for color matching before beginning the production. In digital printing that time is no needed. Reduced expense production is accomplished by printing without plates and with less production processes. Simple procedure makes any type of body to be able to publish easily. It is basic as that it does not require knowledge of prepress or mixing ink.

Variable data printing and customized manufacturing is additionally feasible. The requirements of the clients can be currently swiftly responsed to, depending upon their own hobbies or periods. In addition to the common color prints, the UV inkjet printers permit glossy click to find out more finish, texture print, and embossed effects which adds much more worth to the printed products.

Table Of Contents Litho Lamination (Offset Printing) is a typical printing technique and was the most preferred selection until recently. Litho is the process of printing onto paper liner board and then laminating flooring that onto corrugated paper. Making use of oil and water, it produces a favorable and adverse plate to transfer high-grade shade graphics onto appropriate substrates.

All About Digital Printing

Lithographic presses utilize two print platesa favorable and a negativeto transfer premium shade graphics onto an ideal substratum. The favorable plate, with its smooth surface area, draws in oil-based inks and pushes back water. In contrast, the negative plate, with its rough appearance, takes in water and fends off oil. Rubber rollers are after that used to transfer the picture from the plate to the corrugated surface area.

Corrugated paper can in some cases show to be a difficult surface area to publish on, however Litho prints to a different official statement surface area and is then laminated flooring to it, making it easy to publish high-quality pictures. It can be extremely regular, even for long runs. Actually, the more you print, the cheaper the prices become for Litho.

Report this page